Viral Vectors CDMO Service

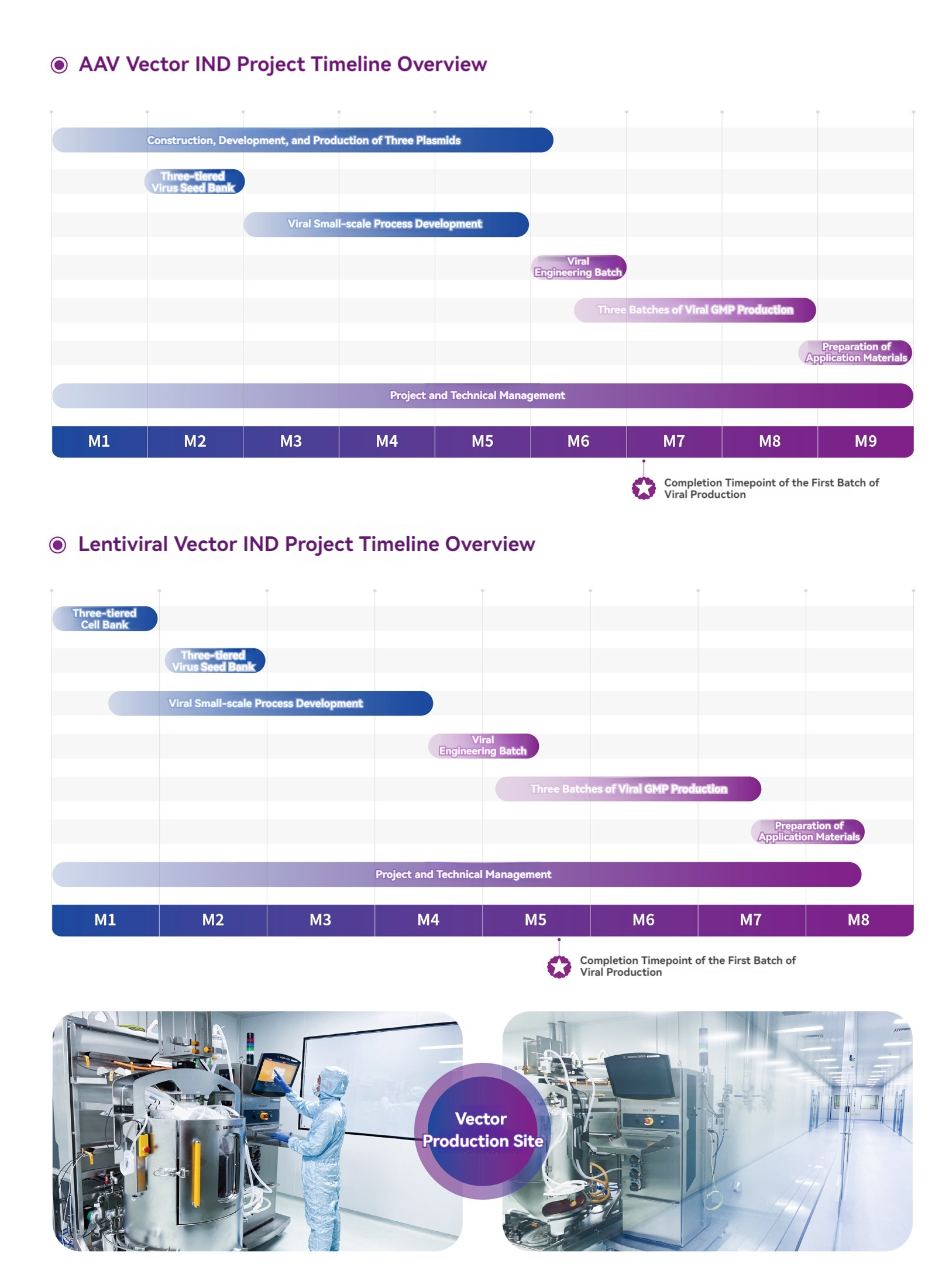

LotusLake BioMedical offers process development and production services for a variety of viral vectors, including lentivirus and adeno-associated virus (AAV). Utilizing a suspension serum-free culture process, we conduct cell culture, transfection, amplification, harvest, purification, and develop and optimize formulation methods while confirming key quality attributes. GMP viral production employs world-class automated fermentation, ultrafiltration, purification, and semi-automated aseptic filling systems, with the entire process using disposable processes and fully closed production methods.

The eukaryotic production area is equipped with four GMP production lines, featuring 20-liter/50-liter/200-liter single-use bioreactors and 14-liter disposable plate carriers for the production of lentiviral vectors, adeno-associated viral vectors, and adenoviral vectors using both suspension and adherent processes. The facilities have an annual capacity of up to 36 batches.